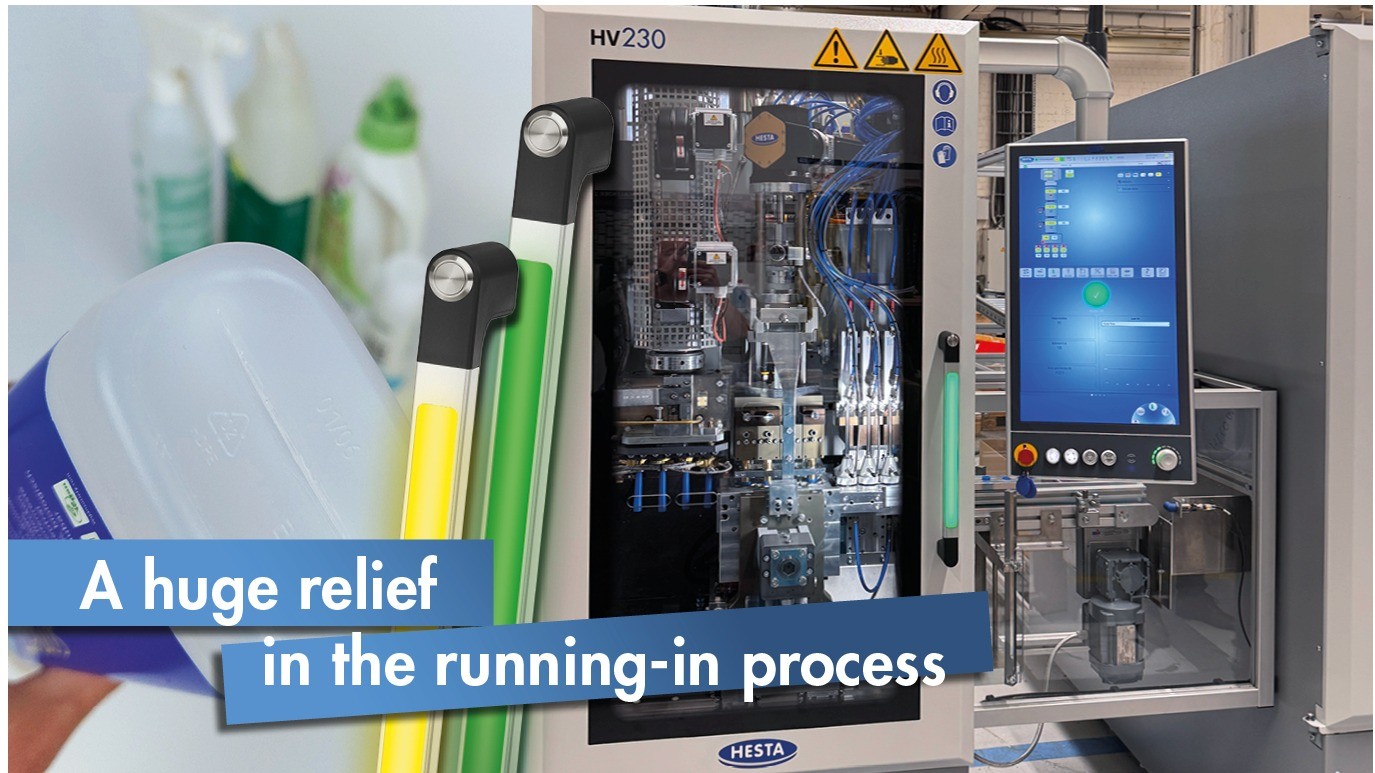

If there is a line on the bottom of the bottle instead of a central injection point, then the plastic bottle was manufactured using the extrusion blow molding process; explained in very basic terms. In this case, it is quite possible that the product was manufactured on a machine from new HESTA.

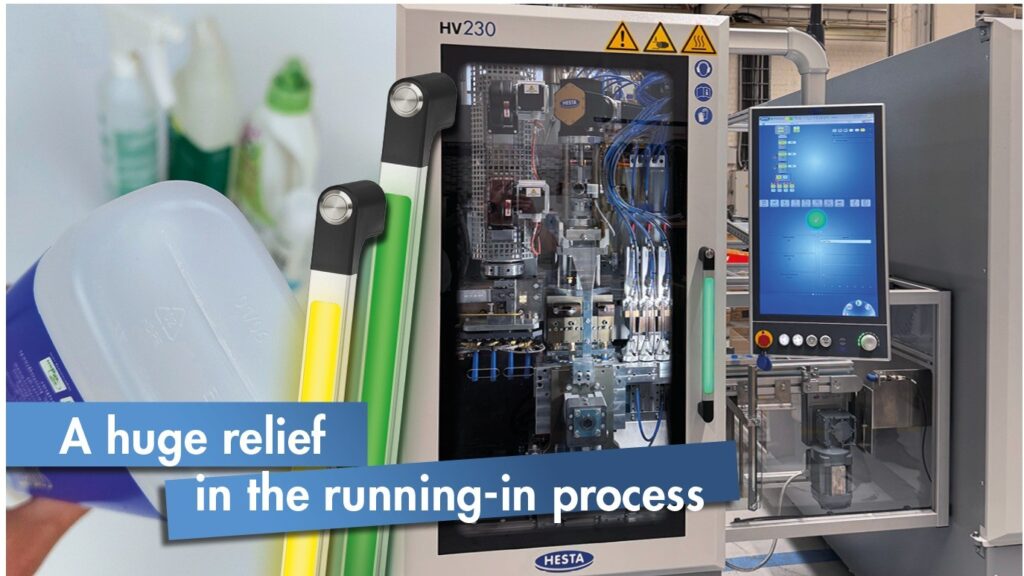

Depending on the size of the system, the functional handle directly on the safety door

can save up to 3 meters of travel each time it is used to unlock and lock the door.

With Swabian attention to detail, the 20-strong team has been developing innovative solutions in the field of extrusion blow molding technology for many years. All systems already impress with a high degree of automation, low personnel requirements, and quick setup – the changeover of tools and products – but there is always room for optimization in the details.

One item on the designers’ wish list was a way to make life even easier for machine operators during the run-in process. During this process, the sensor-secured safety door has to be opened many times, as it can only operate in accordance with CE standards when closed. The impulse to unlock or lock is triggered by a button on the HMI. For 20 years, all new HESTA systems have been available on the market in a fully electric version with convenient PLC control and a touch panel. However, depending on the size of the system, the distance to this button can be up to three meters.

You can find the complete article at:

https://www.krausnaimer.com/de_en/info/im-einfahrprozess-eine-riesenerleichterung