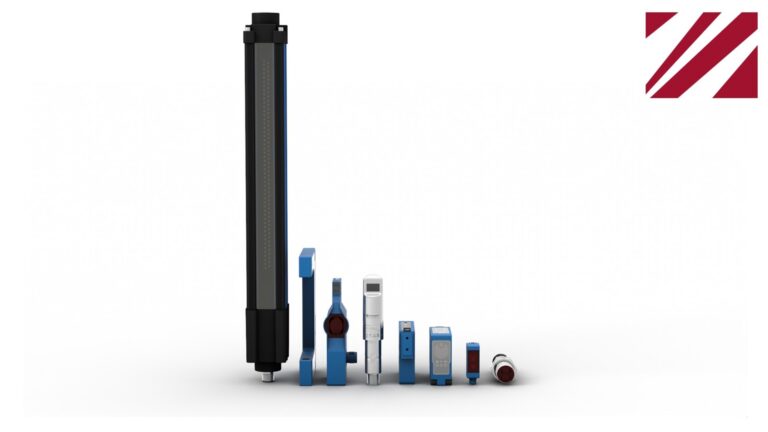

With the P1PY21 series, the wenglor sensoric group is setting new standards in sensor technology. The P1PY21 uses blue laser as the world’s first sensor with time-of-flight technology. With impressive performance: the wintec with blue light delivers precise measurement results even under extreme conditions. Thanks to the shorter wavelength, blue laser light does not penetrate as deeply into the object surface, enabling stable detection in dark, glossy, organic or (semi-)transparent materials. An integrated special filter ensures reliable detection even in the event of interference from high-emitting objects, such as glowing metals. Equipped with proven Dynamic Sensitivity technology, wintec combines precision and innovation with blue light, making it the ideal solution for complex applications in automation technology.

The integrated innovative BlueLine technology is based on short-wave blue laser light with a wavelength of 445 nm and achieves high accuracy on demanding surfaces, such as glossy plastics, dark paints or polished metals. Red glowing surfaces in the metal industry are also reliably detected. The reduced penetration depth of the blue laser ensures safe detection of organic materials and can be operated safely according to laser class 2. The P1PY21 series also handles even uneven surfaces with holes, tears or grid structures with a wide detection range thanks to the large-area line-shaped laser light spot.

The Highlights at a Glance:

BlueLine technology with short-wave blue laser light at 445 nm wavelength

High accuracy on shiny plastics, dark paints, polished metals

Reliable detection of red glowing surfaces

Safe capture of organic materials

Safe operation according to laser class 2

Dynamic jump detection, intensity evaluation, integrated speed measurement and transparent object detection

Large working range of up to 5 meters